- Pusher Type, Walking Hearth and Walking Beam Type.

- Top Fired as well as Top and Bottom Fired.

- Side Discharge as well as End Discharge Types.

- Fuel- oil Fired Types- Heavy furnace oil / LDO / HSD etc.

- Gas Fired Types- Natural Gas / LPG / Propane / Producer Gas / Blast Furnace Gas.

- Solid Fuel Types- Pulverized coal fired.

- Bogie hearth furnaces and chamber type furnaces for steel plants, forging units & foundries.

- Walking beam type normalizing furnace, conveyer type tempering furnace, parabolic spring end heating furnace for automobile industry.

- Roller hearth type continuous annealing furnaces, Bell & Pit pot type batch annealing furnaces, Zinc melting furnaces, etc. for Wire plants and other metal processing units.

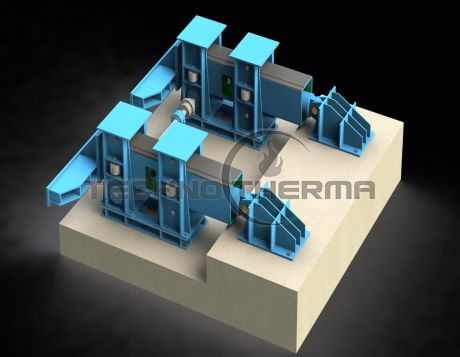

RECUPERATOR

Recuperator is a cross counter flow type metallic heat exchanger used in Reheating Furnaces in order to recover the heat from waste flue gases coming from furnace. Recuperator is fitted in billet reheating furnace in the flue exhaust between the furnace & chimney. The combustion air is preheated in recuperator using heat from waste gases and supplied to the burners. This will result in saving in the fuel consumption.

Various types of recuperators offered by us are:

- 2 pass recuperators for medium heat duty

- 4 pass recuperators for high heat duty

- Straight pipe recuperators for smaller furnace capacities

- Bent pipe recuperators for bigger furnace capacities.

Available for furnace capacities ranging from 2 TPH upto 120 TPH.

FLUE DAMPER :

Flue dampers are used to regulate the flue gas movement and control the furnace pressure. The flap and shafts will be made out of Heat resisting steel. Handle for manual operation is provided. Provision for fitting the actuator also is made for the purpose of automation.

Available in various sizes upto 3000 mm diameter.

CHARGE PUSHER:

Billet charging pushers in following categories are supplied by us:

- Power screw type mechanical pushers for smaller furnaces.

- Single cylinder type Hydraulic pushers for charge length ranging from 1.5 Mtrs. upto 6 Mtrs.

- Double cylinder type Hydraulic pushers for charge length ranging from 3 Mtrs. upto 6Mtrs.

- Three cylinder type Hydraulic pushers for charge length of 9 Mtrs.

- Four cylinder type Hydraulic pushers for charge length of 12 Mtrs.

Pusher machines will be supplied along with Hydraulic power pack units.

HOT BILLET EJECTOR:

Hot billet Ejector machines in following categories are supplied by us:

- Single drive Light model for charge billet length upto 4 Mtrs. and billet weight upto 600 Kgs.

- Single drive Medium model for charge billet length of 4 to 6 Mtrs. and billet weight upto 1200 Kgs.

- Double drive heavy model for charge billet length of 6 to 12 Mtrs. and billet weight upto 2400 Kgs.

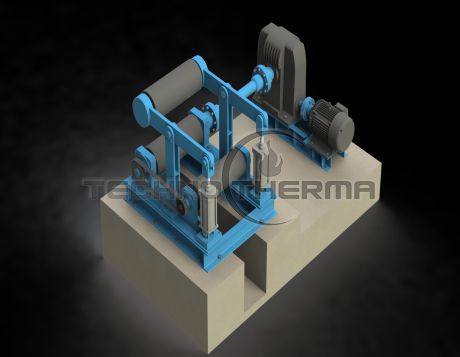

PINCHING CUM PULL OUT ROLL ASSEMBLY:

This machine is used in combination with the Ejector machine where the furnace chamber width is more than 6 metres.

Available in 3 sizes with billet weight ranging from 600 Kgs. upto 2400 Kgs.

All type of Refractories and Insulating materials such as:

- Standard Fire bricks in regular & high alumina grades.

- Shaped bricks/blocks in all alumina grades such as arch bricks, abutment blocks, tiles, wall holding bricks, roof shapes, etc.

- Magnesite bricks, chrome magnesite bricks, basic mortars, etc.

- Insulation bricks (hot & cold face), calcium silicate blocks, mineral wool mattresses, glass wool mattresses, etc.

- Conventional castables, low cement castables, insulating castables, etc.

- Precast and pre-fired blocks for Reheating furnace hearth top applications

- Precast and pre-fired primary and secondary burner blocks and other shapes.

- Ceramic fibre blankets, modules, paper and boards

- Refractory and insulating mortars in various grades

- Burners and accessories for various applications and for oil, natural gas, producer gas & pulverized coal firing.

- Combustion air blowers, 2-stage high pressure atomising air blowers, I.D. Fans and dilution air blowers.

- Fuel oil pumping, filtering and heating systems, Fuel oil tank outflow heaters, online oil pre-heaters and accessories.

- Gas line supply manifolds for pressure regulation & safety interlocks

- Gas line valves, filters & accessories.

- Air line butterfly valves and expansion bellows.

- Coal pulverising and coal feeding systems.

- Simple, yet effective, automatic furnace temperature control systems for oil & natural gas firing using stand alone type controllers.

- Automatic Furnace pressure control system using stand alone type PID controller.

- Automatic continuous excess oxygen control systems.

- Flame failure safety and auto ignition system using automatic burner sequence controllers for natural gas fired furnaces.

- Mass flow measurement based accurate furnace temperature control systems using stand alone type PID controllers.

- Complete furnace automation & safety schemes based upon PLC system and dedicated software.